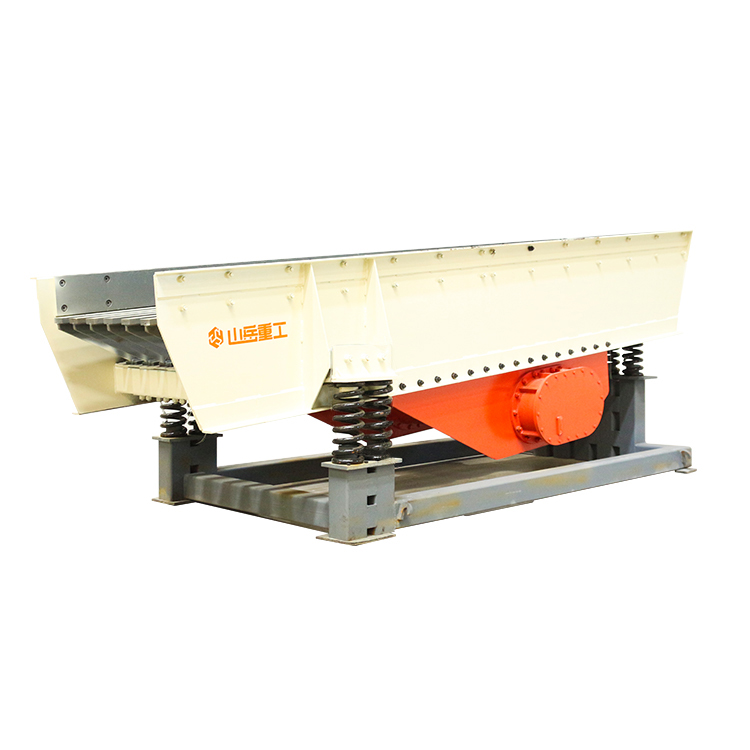

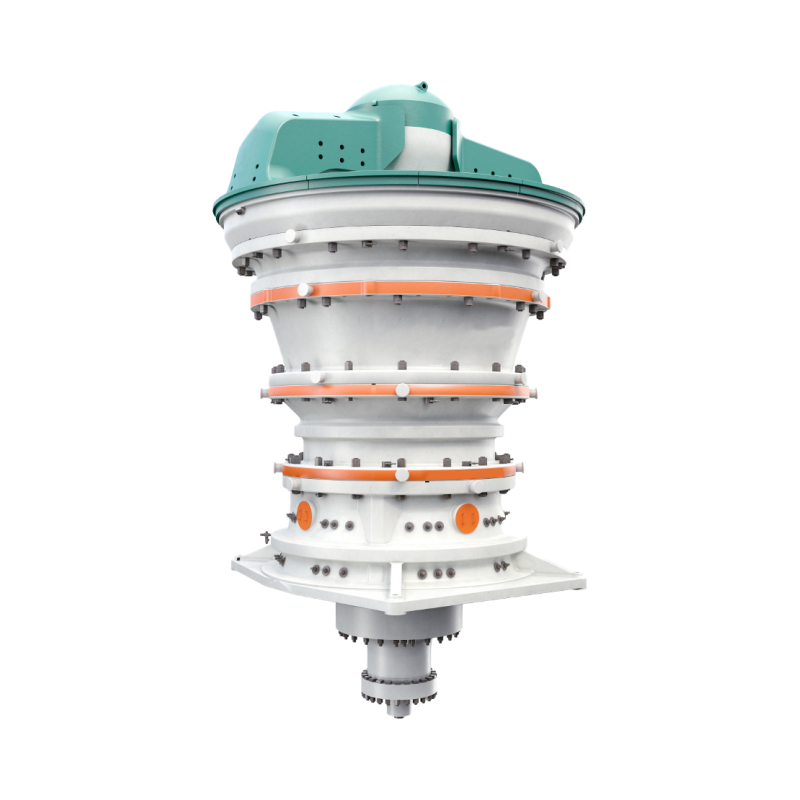

Shanyue High Efficient VSI Impact Crusher

Production Description

This machinery is used to crush hard and crispy materials such as iron, copper, kustelite, molybdenum, lead zinc, tungsten, manganese, frit, fire-proof materials, ceramics, cement, artificial sand, aluminium oxide, talc, olivine, feldspar, fluorite, limestone, silicon carbide, steel slag and other ultra-hard and medium-hard materials. It is also applicable in fine crushing and medium crushing operations of abrasive materials. Y-VSI is an energy efficient equipment well suited to crushing and grinding.

The feed size of this machine is shown in the table of performance parameters. Materials whose feed size is greater than the specified maximum are prohibited from entering into the crusher. Maximum ratio of feed water is 10%, and ore that has been processed by ore washing machine can directly enter the crusher. The discharge size of the crusher is less than 10MM, accounting for 60%~90%. The ore is easy to crack. The smaller the feed size, the higher the proportion

of qualified product, a

description2

Technical Parameter

Product model |

Y-VSI8522 |

Y-VSI9532 |

Y-VSI1145 |

||||||

Capacity (t/h) |

Flash feed |

90-140 |

120-190 |

160-250 |

220-340 |

300-460 |

330-510 |

375-580 |

430-660 |

Full feed |

70-120 |

95-155 |

125-205 |

170-270 |

230-350 |

255-395 |

290-450 |

330-510 |

|

Maximum feed size (mm) |

Soft material |

40 |

45 |

50 |

|||||

Hard material |

40 |

40 |

45 |

||||||

Installation power (kw) |

160 |

200 |

250 |

2*160 |

2*200 |

2*220 |

2*250 |

2*280 |

|

Driving modules |

Single motor |

Double motor |

|||||||

Rotating speed (r/min) |

1200-1800 |

1100-1700 |

1000-1500 |

||||||

Weight (kt) |

13 |

16.5 |

19 |

||||||

description2

Advantages and Characteristics

1. Y-VSI hydraulic set facilitates entrance into the machine during maintenance, which shortens the parking time and facilitates installment.

2. Y-VSI vertical shaft impact crusher controls the grain size of the products by optimizing multiple variables by ways of changing the rotor speed, usig different ring-shaped crushing chamber, adjusting the waterfall flow and using rotors with different diameters.

3. Due to its low requirements for maintenance and easy operation, Y-VSI serves as a perfect match with the crusher in place or planned to be installed.

4. Quick and simple to install. The crusher adopts minimal support structure with high mobility.

5. Good control of the grain size. Maximized or minimized production of fine materials based on needs.

6. Production of high grade cubic products.

7. Excellent performance of mineral liberation and improved mineral recovery.

8. Selective crushing.

9. Models available for fine-crushing and fourth-level crushing.

description2

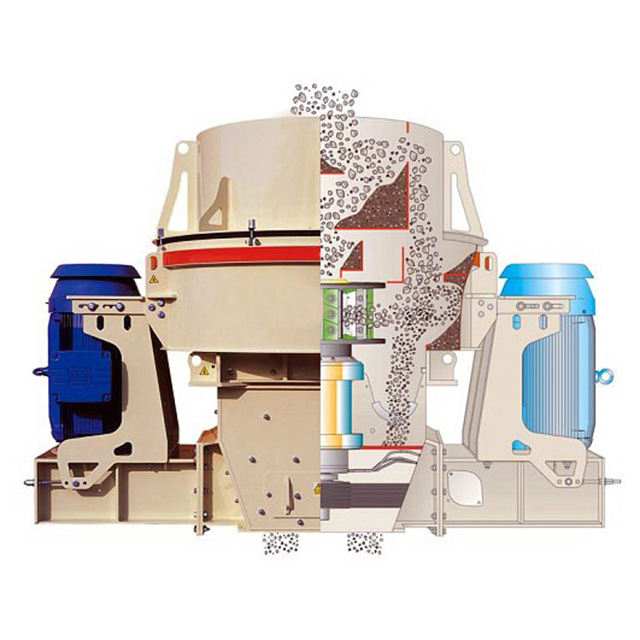

Detailed diagram

description2

Application

VSI sand making machine is used for highway, high-speed railway, high-rise building, municipal engineering, hydropower dam construction, concrete mixing station to produce sand and gravel aggregate, and it is the equipment in the field of artificial sand making and stone shaping.

description2

Working Principle

Y-VSI Series High Efficient Impact Crusher adopts a falls flow feeding system and introduces the second material flow into the crushing cavity with a certain controlled amount. This increases the quantity of materials or the density of crushing cavity and facilitates the exchange of energy between particles. Violent collisions ensue when materials entering the crushing chamber meet with suspended materials and material gaskets. The entering materials will then collide with materials again projected by the wheel, and will eventually be discharged from the crushing chamber due to loss of energy. As the crusher is in operation, the hydraulic waterfall flow feeding system enables the user to adjust the waterfalls flow size through an external hydraulic device and control the grain size in an accurate way. The waterfalls flow system can be adjusted through hydraulic pressure or manually. This enables the crusher to adapt to changes of the feed and guarantees the quality of the products and the proportion of fine materials.

description2