Shanyue Mining Machinery Hot Sale Jaw Crusher

| Feed Size | Process Capacity | Motor Power |

| 0-1275mm | 45-1435t/h | 55-400kw |

Product introduction

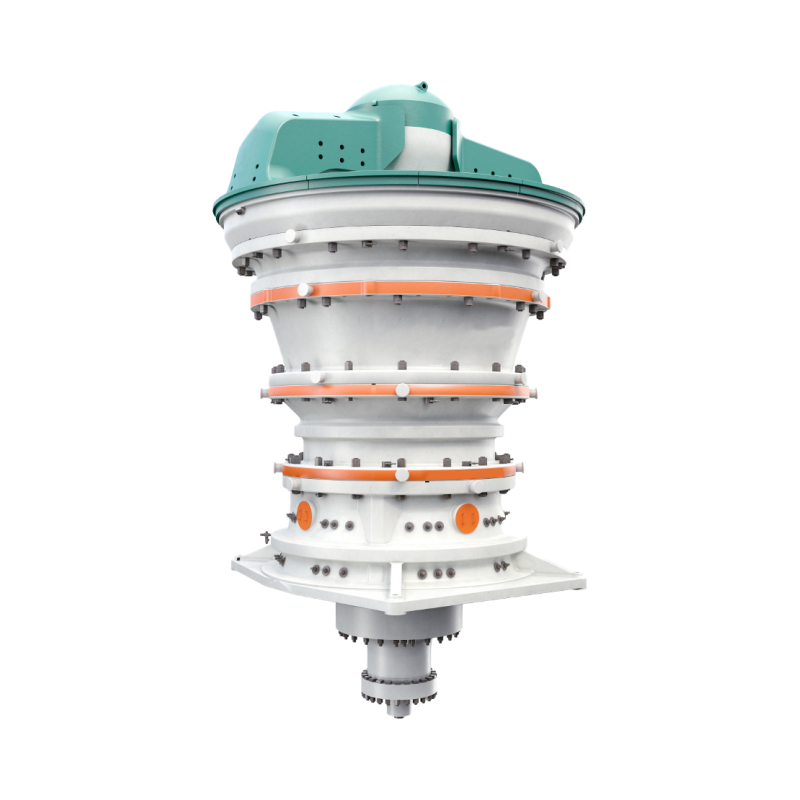

PEC series compound pendulum jaw crushers apply the most advanced crushing technology in the world. They are products with high efficiency and the best choice when crushing various hard, abrasive and corrosive materials. The motor and host apply a compact and integrated structure, symmetric V-shaped crushing chamber and wedge adjustment devices, which give the crushers high capacity and strength. The series are suitable for materials with compressive strength less than 280MPa. The series are wide applied in metallurgy, mining industry, chemical industry, cement, construction, etc.

description2

Technical Parameter

Product model |

PEC 500*750 |

PEC 600*900 |

PEC 750*1060 |

PEC 950*1250 |

PEC 1200*1600 |

PEC 1500*2000 |

|

Feed inlet width (mm) |

750 |

900 |

1060 |

1250 |

1600 |

2000 |

|

Feed inlet depth (mm) |

500 |

600 |

750 |

960 |

1200 |

1500 |

|

Power (kw) |

55-75 |

90 |

110 |

160 |

250 |

400 |

|

Crusher weight (kg) |

8000 |

11000 |

22000 |

38000 |

72000 |

125000 |

|

Material size (mm) |

Closed side setting (mm) |

Processing capacity (t/h) |

|||||

0-60 |

40 |

45-65 |

|

|

|

|

|

0-75 |

50 |

60-80 |

|

|

|

|

|

0-90 |

60 |

70-90 |

80-100 |

|

|

|

|

0-105 |

70 |

85-115 |

95-120 |

105-145 |

|

|

|

0-120 |

80 |

100-135 |

115-140 |

120-165 |

|

|

|

0-135 |

90 |

115-150 |

130-160 |

140-190 |

|

|

|

0-150 |

100 |

130-175 |

150-180 |

160-215 |

190-240 |

|

|

0-185 |

125 |

160-220 |

190-230 |

200-270 |

240-300 |

|

|

0-225 |

150 |

200-265 |

230-280 |

250-325 |

290-350 |

460-610 |

|

0-260 |

175 |

|

270-335 |

295-385 |

340-430 |

495-695 |

630-890 |

0-300 |

200 |

|

|

345-445 |

430-545 |

560-790 |

710-1000 |

0-340 |

225 |

|

|

|

455-570 |

625-880 |

785-1105 |

0-375 |

250 |

|

|

|

515-650 |

685-965 |

865-1215 |

0-410 |

275 |

|

|

|

|

745-1055 |

940-1320 |

0-450 |

300 |

|

|

|

|

815-1145 |

1015-1435 |

description2

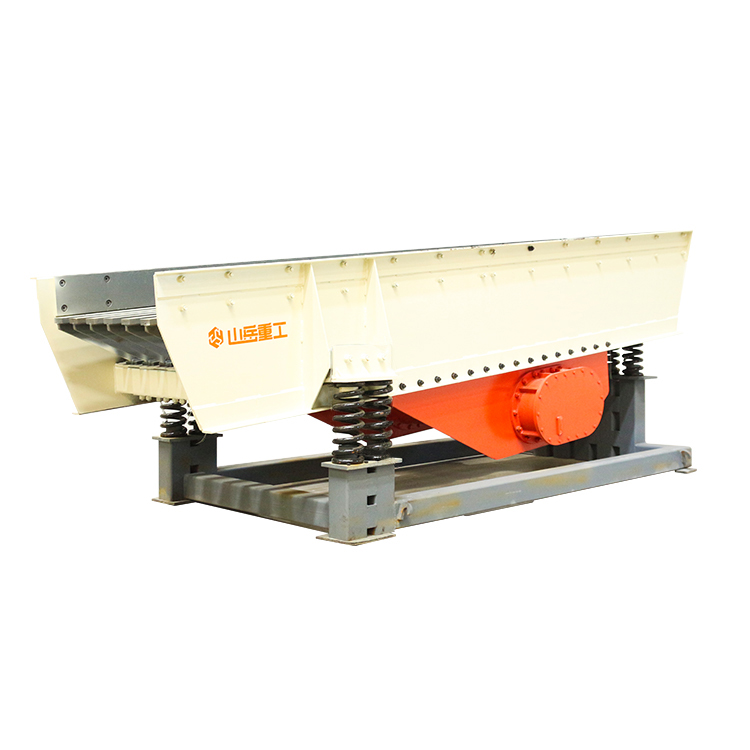

Advantages and Characteristics

This series of crushers apply advanced manufacturing technology and raw materials with high quality, which greatly prolongs the life of the product. The bearing seat adopts an integrated cast steel structure to ensure it can fully support the rack of crushers, which greatly increases the radial intensity of the bearing seat. The traditional detachable bearing seat does not possess this advantage. The symmetric V-shaped chamber makes the actual feed inlet width consistent with the nominal feed inlet width, which widens the feeding size. The wedge setting adjustment is simpler, much safer and faster than outdated shim adjustment systems. Abrasion resistant materials are used to prolong the life of toothed plate and costs are reduced.

description2

Detailed diagram

description2

Application

Our products are widely applied in metallurgy industry, mining industry, chemical industry, cement and construction industry.

description2

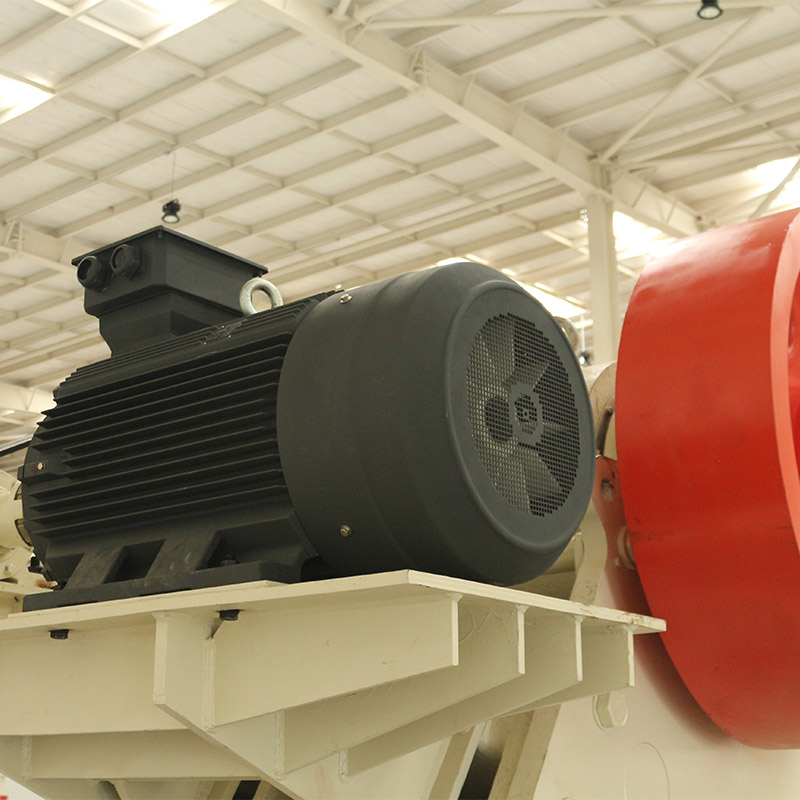

Working Principle

This series have the same main structure as traditional jaw crushers. The main components are rack, eccentric shaft, pulley, side guard plate, toggle plate, slack adjusting rod, restoring spring, fixed toothed plate and swing toothed plate. The motor transmits power through belt, drives the moving jaw upward and downward surround the eccentric shaft. The angle between toggle plate and moving jaw increases when moving jaw moves up and it will push the swing toothed plate toward fixed toothed plate. During this process, the materials are crushed in multiple ways. When the moving jaw moves down, the angle between toggle plate and moving jaw decreases, so the swing toothed plate moves away from the fixed toothed plate by the pulling force of rod and spring. Products crushed will be discharged from the outlet of the crusher. The bulk production is finished by these cyclic activities.

description2