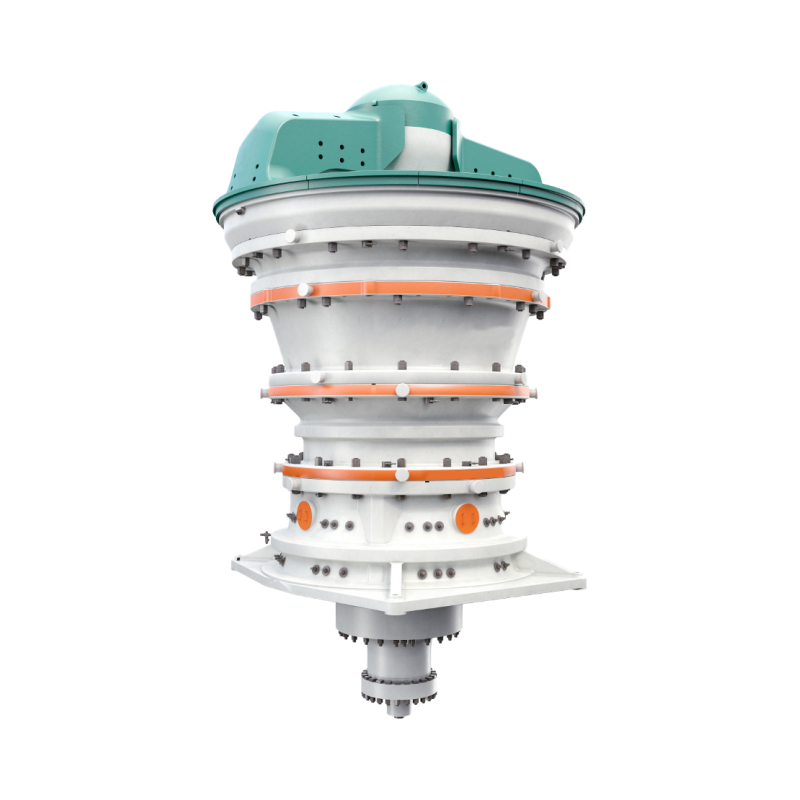

Shanyue New Design Large Capacity Gyratory Crusher

Difference Between Gyratory Crusher And Jaw Crusher (How To Select)

Compared jaw crusher with gyratory crusher, they have their own advantages and disadvantages.

The advantages of gyratory crusher are high productivity, low power consumption, stable operation, small vibration, large crushing ratio, uniform product particle size. The disadvantages are high equipment cost, big machine body, high workshop requirements, heavy weight, inconvenient transportation, unsuitable for crushing sticky ores, and complicated operation and maintenance. In contrast, the jaw crusher has the advantages of simple structure, low manufacturing cost, convenient maintenance and repair, reliable operation, small machine height, easy configuration, and not easy to block the ore with high moisture and high viscosity. The disadvantage is low productivity, high power consumption, the vibration is large, the crushing ratio is small, and the crushed material particle size is not uniform enough.

The gyratory crusher is suitable for factories and quarries with large production volumes. According to experience, if one jaw crusher can meet the production requirements, then the jaw crusher should be used; if two jaw crushers are needed, one gyratory crusher can be considered.

description2

Technical Parameter

|

Model |

42-65 |

50-65 |

54-75 |

62-75 |

60-89 |

60-110 |

|

Max Feed Size(mm) |

1065 |

1270 |

1370 |

1575 |

1525 |

1525 |

|

Max Power (kw) |

375 |

375 |

450 |

450 |

600 |

1000 |

|

Discharge Opening (mm) |

Processing Capacity(t/h) |

|||||

|

125 |

||||||

|

140 |

1635 |

|||||

|

150 |

1880 |

2245 |

2555 |

2575 |

||

|

165 |

2100 |

2625 |

2855 |

3080 |

4100 |

|

|

175 |

2320 |

2760 |

3025 |

3280 |

4360 |

5575 |

|

190 |

3215 |

3660 |

4805 |

5845 |

||

|

200 |

3385 |

3720 |

5005 |

6080 |

||

|

215 |

5280 |

6550 |

||||

|

230 |

5550 |

6910 |

||||

|

240 |

7235 |

|||||

|

250 |

7605 |

|||||

description2

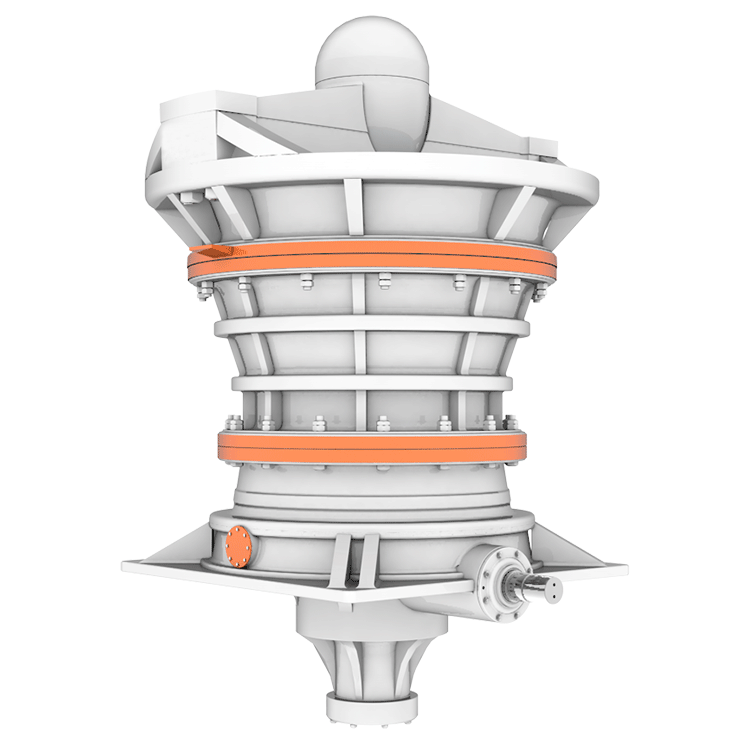

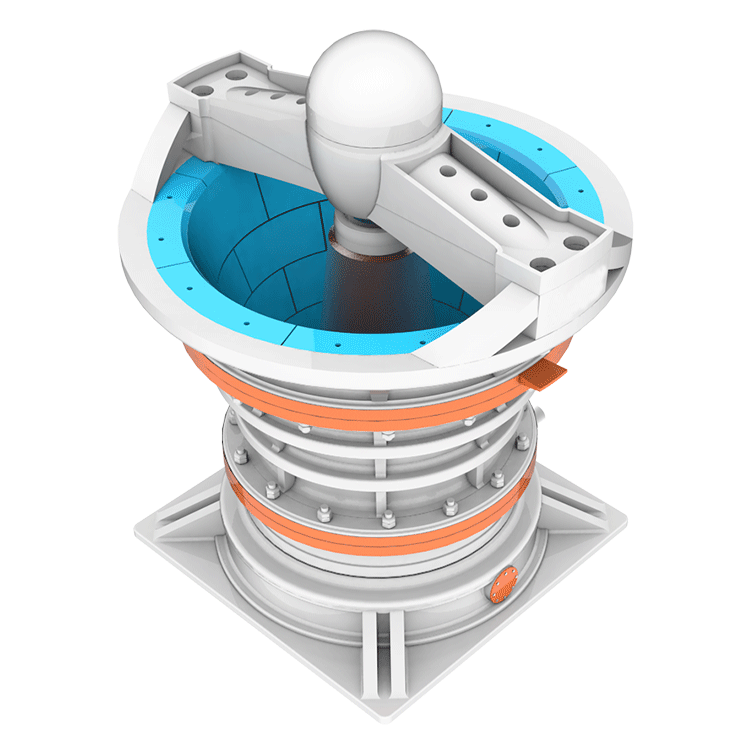

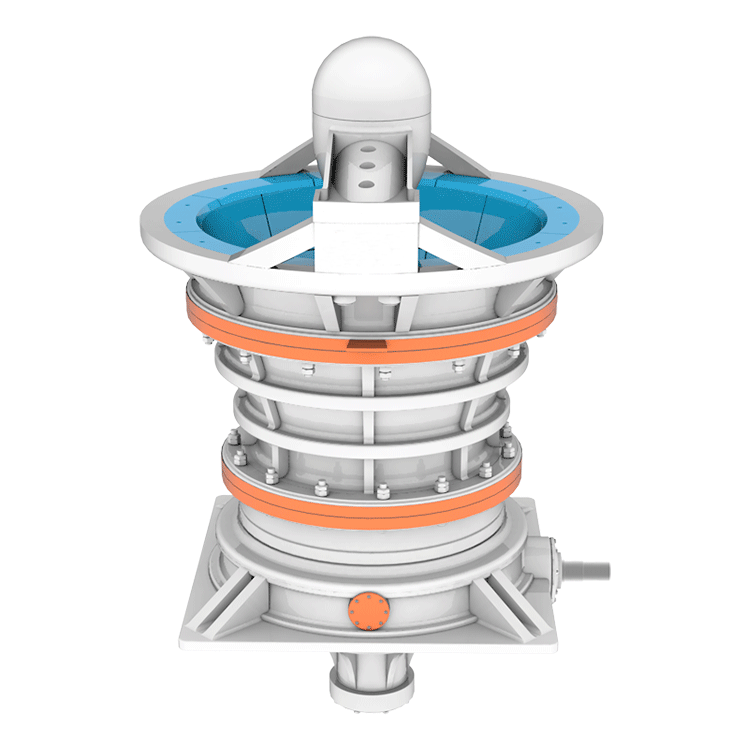

Detailed diagram

description2

Working Principle

When the equipment starts running, the motor drives the eccentric sleeve to move through the horizontal shaft and bevel gear. The crushing cone moves under the drive of the eccentric shaft, thereby swinging back and forth between the crushing walls. Then the materials in the crushing cavity are continuously squeezed and crushed. When the particle size is smaller than the size of the discharge opening, they will be discharged from the bottom.

description2