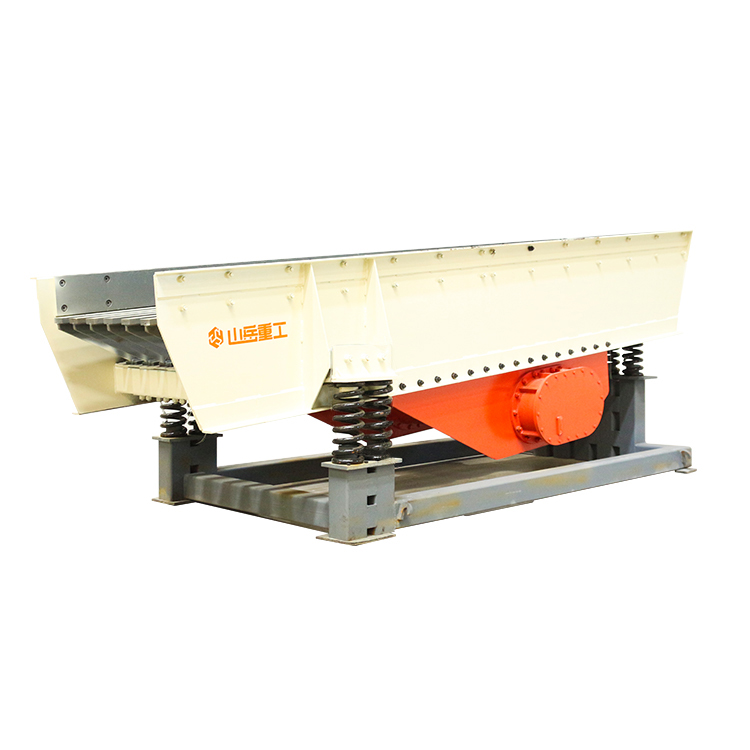

Shanyue New Products Linear Dewatering Vibrating Scree Vibrating Sieve Machine

Product introduction

The characteristics of high-frequency dewatering screen is efficient dehydration equipment, the utility model has the advantages of reasonable structure, unique and novel, using vibration motor as vibration source material throwing motion, to achieve the purpose of screening processing, mainly for small or tiny material classification and dewatering and slime recovery, such as dry tailings, concentrate dewatering, slime separation industry, with large quantity, full dehydration, obvious technical and economical effect, applicability wide.

description2

Technical Parameter

Product model |

Screen size(mm) |

Screen area (m2) |

Screen material |

Capacity (t/h) |

Power (kw) |

ZDTS1236 |

0.2, 0.3, 0.5 |

4.32 |

Polyurethane |

20-35 |

2*2.2 |

ZDTS1836 |

0.2, 0.3, 0.5 |

6.48 |

Polyurethane |

30-50 |

2*3 |

ZDTS2436 |

0.2, 0.3, 0.5 |

8.64 |

Polyurethane |

60-80 |

5.8*2 |

ZDTS3060 |

0.25-50 |

18 |

Polyurethane Staninless steel |

150-350 |

30*2 |

description2

Advantages and Characteristics

1.the use of dual vibration motor excitation, structure compact and rugged, get rid of the disadvantages of traditional eccentric vibrator structure, oil spills, wear large, large noise, inconvenient maintenance and the like.

2.The side body guard board of the dewatering sieve is stuck with the rubber to ensure that the dewatering screen is not affected by the abrasion, and the deformation is broken, and the pollution of iron to the material is reduced.

3.high-frequency dewatering screen screen using the embedded wear-resistant urethane combination screen, its life than traditional metal screen high 3-10 times, to avoid the metal frame screen and ore direct collision, reduce noise, reduce metal screen heavy feeling.

4.the dewatering screen of the damping device is a rubber vibration damper, more suitable for wet conditions, both damping and durable.

5.efficient multi frequency dewatering sieve with sieve plate on the side of the hole, let some water from the hole rapid outflow and accelerate the dehydration speed. In addition, but also to avoid the due to the water splashed to the motor caused by damage phenomenon.

description2

Detailed diagram

description2

Application

Dewatering Vibrating Screen is widely used in the mining industry, coal industry, construction material, metallurgy industry, and chemical industry. The linear motion dewatering vibrating screen can be used for dewatering, desliming, demineralization and dry discharge of mining.

description2

Working Principle

1. high frequency dewatering screen using a unique vibration motor as vibration exciter. Motion trajectory is more stable and reliable.

2. when the two motors for synchronous reverse rotation, the eccentric block to produce the vibration force in parallel with the direction of the motor axis offset, are stacked in the direction of the vertical shaft of the motor is a resultant force, the sieving machine trajectory is a straight line.

3. two shaft relative to the screen surface inclination angle in the vertical direction, in vibration force and material from the combined effect of gravity, sieve surface material along the continuous leap forward movement.

4,.in and meet screen surface, so that less than a mesh material and water penetration screen surface, in order to achieve dehydration, desliming and grading.

description2