Shanyue Portable Mobile Crushing And Screening Station

Combination of mobile crushing and screening plant

The mobile crushing station is a mobile production line that integrates feeders, crushers, screening systems, debris sorting devices and conveyors, and is equipped with a traveling mechanism.

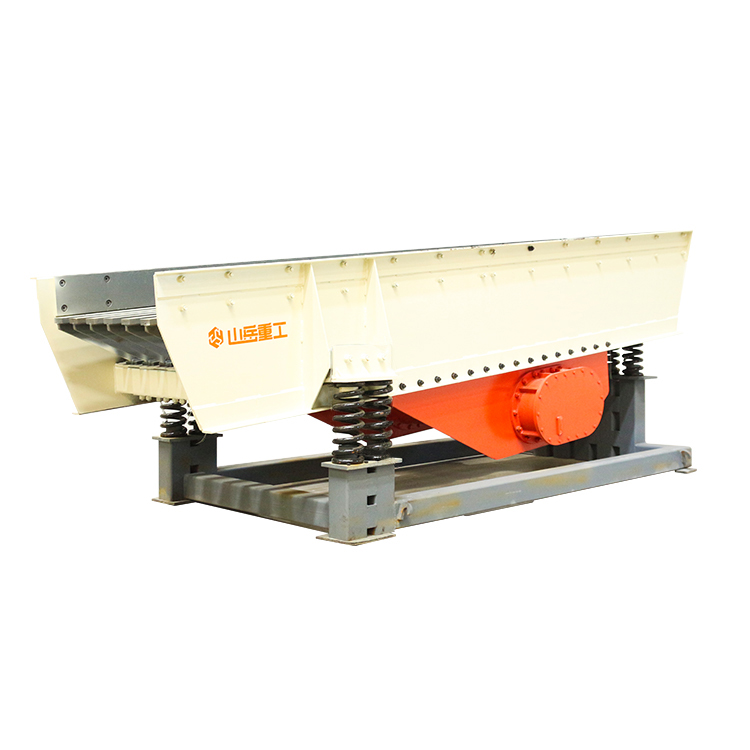

1. Feeding system:

In order to ensure uniform feeding, a vibrating feeder is needed to be installed in front of the crusher. After vibrating the materials, they are slowly fed into the crusher. Materials with smaller particles will fall in the gaps between the rods, playing a pre-screening role.

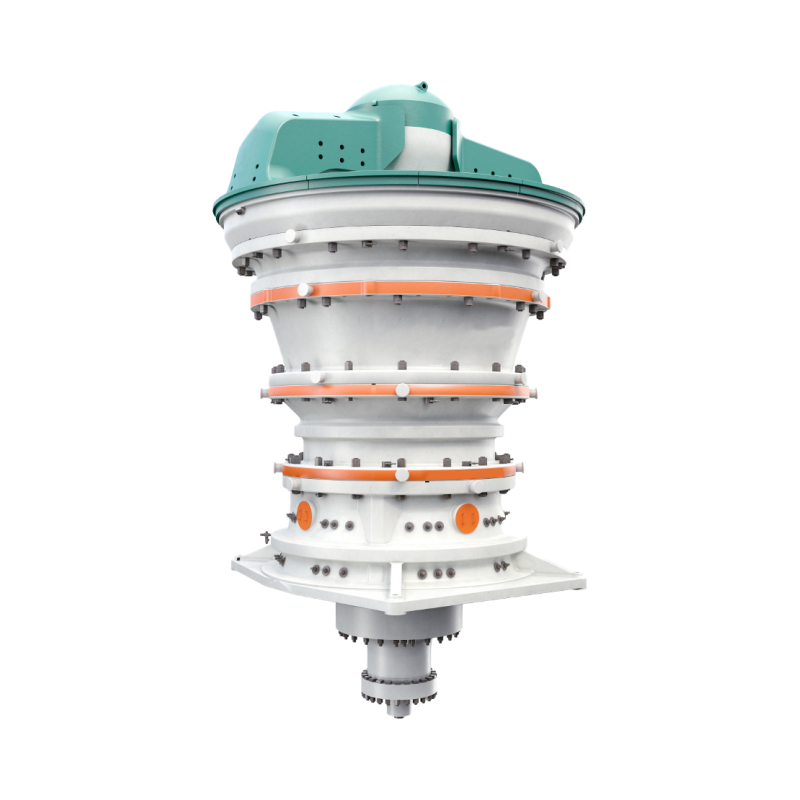

2. Crushing system

The crushing system is the core of the entire equipment. When it works, it crushes ore raw materials into finished materials with small particle sizes to ensure that the crushed materials are granular and reduce the content of flake materials. At the same time, the particle size distribution must be uniform, so the crusher has specific requirements for capacity, efficiency, quality of crushed material. A mobile crushing and screening production line can be composed of multiple crushers.

3. Screening system

The screening system is set up to meet the requirements for particle size sorting. In order to ensure the quality of the crushed material, the blocks with larger sizes that cannot meet the requirements after primary crushing are transported back to the crusher for re-crushing.

4. Conveyor system

The conveyor system has three functions in mobile crushing station. The first is to transport ore between various levels of crushing and screening equipment; secondly, it is used for the return of crushed materials in a closed loop; and finally, it transports the finished materials to different locations for stacking by size difference. The conveying machinery of the mobile crushing station is mainly belt conveyors.

5. Mobile system

The mobile system is divided into two types: crawler type and tire type.

The tire-type mobile station has high chassis and small turning radius, making it easy to drive on roads and quickly enter the construction site. It can save time, have high flexibility, and uses a vehicle-mounted generator set to provide continuous power for the equipment.

The crawler-type mobile station has low center of gravity, smooth movement, low ground contact pressure, good passability, and has good adaptability to mountains and wetlands. It generally adopts a fully hydraulic drive system. The power unit of the crawler-type mobile station has a large driving force, and the position of the equipment can be adjusted by itself during operation, without the need for additional traction equipment.

description2

Advantages and Characteristics

1. High mobility and reliability: The combination of crushing and mobile terminals is a technological breakthrough in the crushing industry. The mobile crushing station not only retains the crushing process of traditional crushing equipment, but also realizes fast mobile work and has better adaptability to the environment.

2. Small footprint, high efficiency work: The mobile crushing station can complete the work of the crushing production line, integrating feeding, crushing and screening. Compared with traditional crushing production, transportation integration saves production space and simplifies the crushing process. , making the crushing work easier and faster, and easy to use in workplaces with narrow production environments.

3. Simplify the work stage, reduce environmental pressure: Due to the simplification of the crushing work process, the power demand of the crushing equipment is reduced, and the amount of dust generated during the crushing process is effectively managed. Good noise protection measures can also reduce stressful environments, which complies with current environmental protection. This is a representative model of high-rate energy-saving production equipment.

4. Diversified crushing, various combinations: The crushing part of the mobile crushing station can be transported in various forms. Different types of crushing parts can choose different crushing sites. It can also be processed and customized according to actual needs.

description2

Detailed diagram

description2

Application

Mobile crushing stations (mobile crushers) are mainly used for material processing that often require relocation operations in metallurgy, chemical industry, building materials, water and electricity, etc., especially for mobile stone operations such as highways, railways, and water and electricity projects.

description2